Professional Software Suite

Specialized Engineering software with video demonstrations

Silo3D Software

Comprehensive silo design and analysis tool with 3D visualization. Handles bulk material properties, flow patterns, structural calculations, and foundation design.

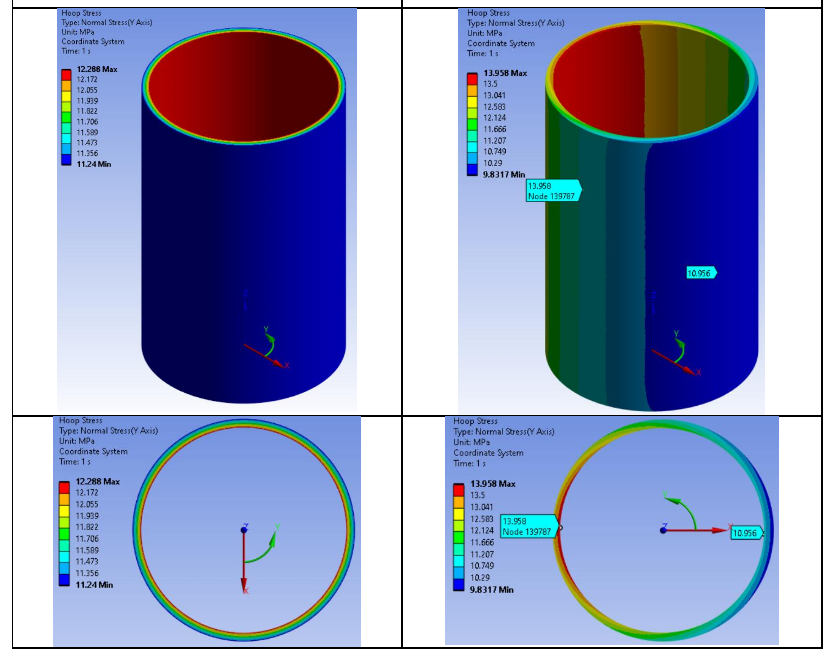

Nozzle Stress Analysis

Calculate stresses in cylindrical and spherical shells at nozzle junctions per WRC Bulletin 537/107. Handles external loadings and reinforcement pad analysis.

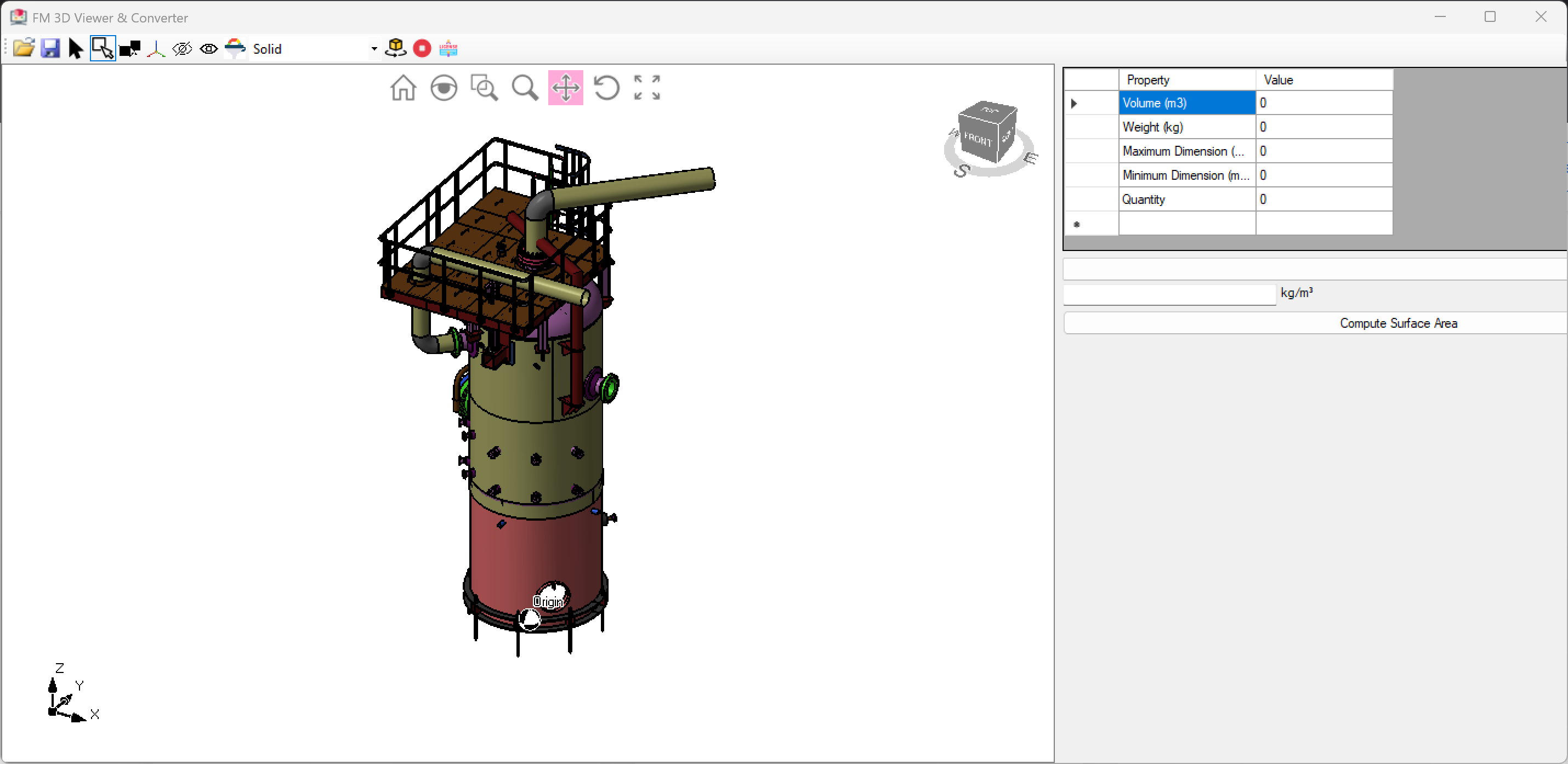

FM 3D Model Viewer

Windows application for viewing and converting 3D files. Calculate volumes, weights, surface areas with material density database and measurement tools.